Processing capacity; 1000KG/H

Scope of application; Dry battery, lithium battery

Component parts; Crushing, electrostatic separation, vibrating screen and other equipment.

Dear [Lithium battery crushing and recycling equipment] customer, thank you for visiting the Asia recycling Equipment rest assured enterprises Maoxin Machinery Israel Lithium battery crushing and recycling equipment online promotion sub-station official enterprise website! Over the years, Maoxin Machinery has insisted on taking research and development as the basis of survival, and constantly improved the application of new technologies in [Lithium battery crushing and recycling equipment] products! This is what the winners look like: our recycling waste lithium batteries experts take Lithium battery crushing and recycling equipment production to the next level. If you want to know more about the application of [Lithium battery crushing and recycling equipment] product new technology in practice, please call Maoxin Machinery [Lithium battery crushing and recycling equipment] technical consultation hotline: [+86 18539447368] to learn more new information!

Scrap lithium battery processing equipment applicable materials:

Processing capacity; 1000KG/H

Scope of application; Dry battery, lithium battery

Component parts; Crushing, electrostatic separation, vibrating screen and other equipment.

Product introduction; The recycling of copper and toner in waste lithium battery materials can be realized through the combined process of hammer crushing, vibrating screening and air separation.

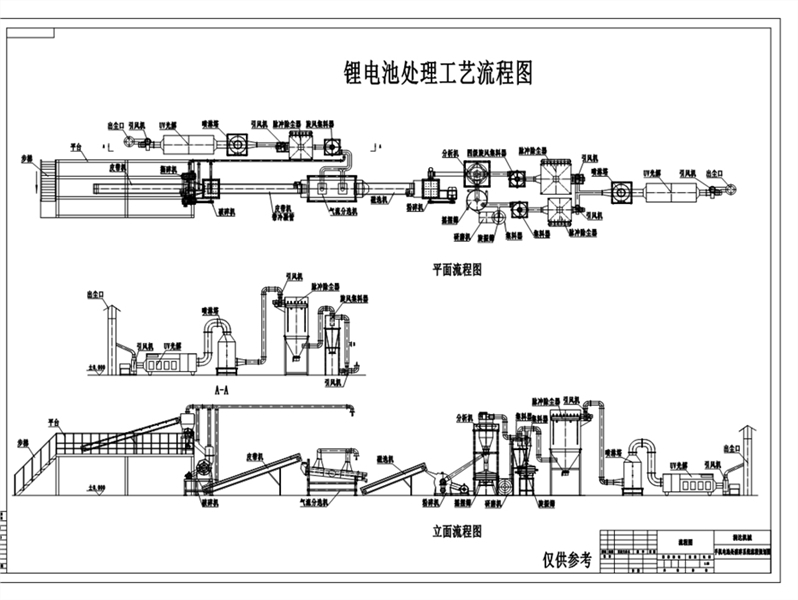

Scrap lithium battery equipment process introduction:

The scrapped lithium battery is sent by conveyor into a shredder for shredding, and the shredded material is sent through the conveyor to the two-stage multi-tool crusher for secondary crushing, and the materials after secondary crushing enter the conveyor at the same time, magnetic separation equipment can be set up to separate the iron in the material. The material after separation is sent to the air separator by the conveyor, the separator paper in the positive and negative electrodes is separated by the induced draft fan and the cyclone feeder, and the positive and negative electrode pieces after separation are entered into the three-level grinder for fine crushing, and the material is crushed to about 20 mesh. The crushed material is filtered by the negative pressure system into the cyclone separator for dust filtration, and through two air separation, so that different density of substances are stratified, and then the positive and negative electrode materials and copper, aluminum, nickel and other materials, and all the ultrafine dust is collected by the negative pressure system into the pulse dust collector. The exhaust gas of the filter * will continue to be sent by the negative pressure system to the exhaust gas treatment equipment for air purification, so that it can meet the national emission standards and then be discharged at high altitude.

Scrap lithium battery processing equipment process flow:

Cobalt, lithium, copper and plastics in waste lithium batteries are valuable resources and have high recycling value. Therefore, scientific and effective treatment of waste lithium batteries not only has significant environmental benefits, but also has good economic benefits. Lithium battery is mainly composed of shell, positive electrode, negative electrode, electrolyte and diaphragm. The positive electrode is formed by coating lithium cobaltate powder on both sides of the aluminum foil collector through PVDF which acts as a bonding agent. The structure of the negative electrode is similar to that of the positive electrode, which is composed of carbon powder bonded to both sides of the copper foil collector. At present, the research on the recycling of waste lithium batteries mainly focuses on the recovery of high value positive precious metals cobalt and lithium, and the separation and recovery of negative electrode materials are rarely reported. The copper in the negative electrode of waste lithium batteries (the content of about 35%) is a widely used important supply raw material, and the toner adhered to it can be used as an additive such as plastic and rubber. Therefore, the effective separation of the negative electrode components of the waste lithium battery has a promoting effect on the limited realization of the waste lithium battery resources and the elimination of its corresponding environmental impact. Common recycling methods for waste lithium batteries include hydrometallurgy, pyrometallurgy and mechanical physics. Compared with the wet and fire methods, the mechanical physical method does not use chemical reagents, and has lower energy consumption, which is an environmentally friendly method.

Scrap lithium battery equipment technical parameters:

1, equipment capacity: 0.2~1 ton/hour

2. Overall dimensions: 26311 X 6121 X 6350mm

3, equipment power: ≤129.25KW

4, Power supply: three-phase AC 380V/50Hz,200KVA.

5, can handle waste battery size (mm) : 600 X 600

6, iron recovery (weight %) : ≥ 99%

7, copper aluminum recovery (weight %) : ≥ 98%

8, positive and negative material recovery (weight %) : ≥ 99%

9, noise, dust leakage and exhaust emissions meet the relevant national standards and requirements.

10, site requirements: enterprise room height is greater than 7 meters; Enterprise door width greater than 4 meters, height greater than 5 meters; Load capacity greater than 10 tons.

11, equipment appearance and color: according to enterprise standards.

Reasons for choosing:

Henan Maoxin Machinery Equipment Co., Ltd. based on the advantages of crushing, separation, recycling and recycling processing equipment industry, key words "innovative spirit" crushing, separation, recycling and recycling processing equipment lithium battery crushing and recycling equipment service provider ---- Maoxin Machinery about "professional innovation", Maoxin robots agreed that - we advocate "professional innovation" is not to emphasize blind innovation, It is an innovation built on the professional basis of crushing, separation, recycling and recycling processing equipment. Only when we make ourselves more professional in the field of crushing, separation, recycling and recycling processing equipment can we put forward more constructive and innovative ideas. Professional innovation is also echoing the company's "Maoxin machinery craftman spirit", which can put forward more feasible product suggestions and solutions for the company's crushing, separation, recycling and recycling treatment equipment lithium battery crushing and recycling equipment, such innovation is valuable to customers in the crushing, separation, recycling and recycling treatment equipment industry.

After-sales service:

1, technical experts one to one for customers to guide the selection, accompany customers to visit to understand the product equipment, there are large-scale prototype test machine inspection, free car to send;

2, with the user signed a unified purchase contract, the company to ensure delivery on time, to ensure that each equipment before the enterprise to do all the test machine, quality is guaranteed.

3, provide professional technical training, installation, commissioning and other services, warranty extension for one year, enjoy "lifelong after-sales service".

Maoxin Machinery The reason for becoming a Lithium battery crushing and recycling equipment long-term partner, the key word "learning culture" recycling waste lithium batteries Lithium battery crushing and recycling equipment service provider -- Maoxin Machinery firmly believes that training leads to talent, efficiency and quality. Normalized training is an important part of the work of [Asia recycling Equipment rest assured enterprises Maoxin Machinery Israel Lithium battery crushing and recycling equipment online promotion sub-station] head office. Keep the original intention and study hard. Maoxin Machinery There is no end to the training work, only when it is in progress!

recycling waste lithium batteries technical team customizes for you!

Lithium battery crushing and recycling equipment Solution TOP

Upstream quality is strict! Lithium battery crushing and recycling equipment Intermediate materials play a decisive role in quality! Maoxin Machinery has identified a number of Lithium battery crushing and recycling equipment upstream suppliers with stable quality through years of industry experience. We can provide quality assured Lithium battery crushing and recycling equipment for customers!

Product pre-sale strict quality inspection! What Maoxin can do is, while optimizing the enterprise's product process, strict quality inspection, mass and multi-batch product inspection, to provide Lithium battery crushing and recycling equipment of user-friendly and ensure the implementation of recycling waste lithium batteries solutions.

Be down-to-earth and carry forward the national spirit of craftsman!

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368