PCB dismantling equipment supply line a new generation of automatic dismantling of PCB components, the equipment has a high degree of automation, instead of personnel dismantling, with automatic dismantling function, automatic dust removal function, shorten the dismantling time, and occupy a small area.

Dear Borz [Circuit board dismantling equipment] customer, it is very lucky that you can find us in the vast information! Good Chinese products that are popular around the world! Maoxin Machinery is a Chinese Circuit board dismantling equipment product supplier. Since its establishment, Assisted by science and technology has been deeply involved in the recycling waste lithium batteries field and has provide technological innovation Circuit board dismantling equipment products for recycling waste lithium batteries customers! The following is the relevant information of Circuit board dismantling equipment product organized by Maoxin Machinery for you. Maoxin are willing to provide you with new Circuit board dismantling equipment information to help you make a correct choice!

Circuit board automatic disassembly equipment

PCB dismantling equipment supply line a new generation of automatic dismantling of PCB components, the equipment has a high degree of automation, instead of personnel dismantling, with automatic dismantling function, automatic dust removal function, shorten the dismantling time, and occupy a small area.

Automatic circuit board dismantling machine is used to remove the electronic original from the waste circuit board next equipment, because different components contain different metals, some components contain precious metals such as gold and silver, while some components contain toxic substances, some components can be directly separated and sold, the template after dismantling is also easier to break and separate the copper. At the same time, it greatly reduces the work of the crushing and sorting section, and improves the reuse rate of precious metals.

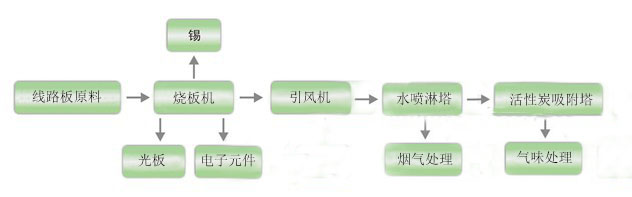

Circuit board dismantling equipment process flow:

Using electric heating or liquefied gas heating, the internal temperature is opened to 120 ° C, the tin will melt, and the electronic components will fall off from the circuit board with the operation of the host. The machine has the advantages of automation, high processing efficiency, low operating cost, small footprint, simple operation, no dust pollution and so on. The treated substrate can be physically recovered from copper and other metals, and the electronic components can be environmentally friendly and harmless recycling. This machine is the ideal circuit board electronic components disassembly equipment.

Circuit board disassembly process diagram:

1, circuit board dismantling machine: the use of electric heating liquefied gas heating two, the internal temperature is controlled at about 150℃, so that the tin on the circuit board loose, with the rotation of the dismantling machine and the circuit board friction, the circuit board and the wall friction, electronic components fall off with the operation of the host.

2. Smoke dust removal cover: Add a smoke and odor cover on the dismantling machine to facilitate the collection of smoke and odor to meet environmental protection standards.

3, water spray tower: the smoke and dust particles through the induced draft fan for water spray purification.

4, activated carbon adsorption box: the gas purified by water spray is adsorbed to remove the smell.

5, plasma purifier: after the activated carbon adsorption box purification of the smoke and then colorless treatment, so as to achieve environmental protection indicators.

6, induced draft fan: the filtered gas is collected and discharged.

Circuit board disassembly equipment outstanding advantage

1, automatic control work, save manpower, generally two people one class.

2, the temperature is automatically controlled by the heating system, without manual participation.

3. Detinning and disassembly are completed in one step.

4, large output, up to 200-500 kg per hour.

5, automatic circuit board dismantling machine is simple and reliable.

6, after separation, they enter their own next segment process to improve economic efficiency.

7, reduce the breaking of components, less precious metal loss.

8, equipped with flue gas treatment Settings for the environment.

Circuit board dismantling machine technical parameters:

|

Device name |

Model number |

Power(kw) |

Number of pieces (set) |

|

Circuit board dismantling machine |

400 |

1.5+0.37 |

1 |

|

Smoke hood |

400 |

|

1 |

|

Water spray tower |

1200 |

2.2 |

1 |

|

Activated carbon adsorption chamber |

1800 |

|

1 |

|

Plasma purifier |

1200 |

1.2 |

1 |

|

Induced draft fan |

400 |

3 |

1 |

|

Dust inlet |

|

|

1 |

Eastern Europe recycling Equipment Circuit board dismantling equipment product supplier--Maoxin Machinery Borz international customer site Based on the advantages of the recycling waste lithium batteries industry, the key words "win-win cooperation" recycling waste lithium batteries Circuit board dismantling equipment service provider -- Maoxin Machinery's business philosophy can be summarized into eight words "honesty based, win-win development". Maoxin Machinery has always implemented this concept well for both its internal employees and external Circuit board dismantling equipment partners, thus gaining long-term good business reputation and cooperative relations in the recycling waste lithium batteries field, and promoting the stable development of Maoxin Machinery.

Let the business fly across the national boundaries,flying around the world. Thank you for attention to the Circuit board dismantling equipment product information, and welcome Borz friends valuable suggestions , If you have any questions about Maoxin Circuit board dismantling equipment, please call Maoxin technical engineer at [+86 18539447368]. Good Chinese products that are popular around the world!

If you want to know what they are doing now and make a major Western country feel threatened, contact and cooperate, and you will directly get the answer!

Gongyi City west Industrial Zone, Henan Province

Phone: +86 18539447368

Email: 18539447368@163.com

Whatsapp: +86 18539447368

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368