Waste capacitors are generally reported as waste from electronic components enterprises, or electronic components on circuit boards. Capacitors can be divided into: aluminum shell, aluminum foil, tin foot (also known as electronic foot, outer tin plated, inner copper plated, inside the iron needle, with magnetic), plastic paint shell, oil and paper.

Maoxin are always looking for new opportunities and new ways of doing things. Customers from Copel, hello! Today is 2025-05-01. Since the Maoxin website http://www.cnmxjx.cn was built, you are the 45126th visitor to Maoxin enterprise! Maoxin Machinery has been committed to technological innovation and product building in the recycling capacitors field since its establishment, and has accumulated to provide continuous innovation [Capacitor processing and recovery equipment] products for many customers!

Introduction of electronic components, capacitance crushing and recycling equipment:

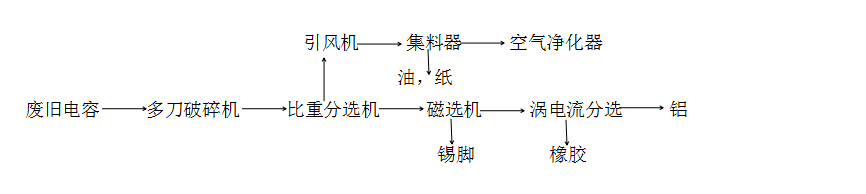

Waste capacitors are generally reported as waste from electronic components enterprises, or electronic components on circuit boards. Capacitors can be divided into: aluminum shell, aluminum foil, tin foot (also known as electronic foot, outer tin plated, inner copper plated, inside the iron needle, with magnetic), plastic paint shell, oil and paper. The smaller the capacitor, the higher the value, generally speaking, the capacitance aluminum content accounts for about 11%-26%, the tin foot accounts for about 15%, and the aluminum foil accounts for about 8%. Aluminum-plastic separation equipment is mainly used for crushing and sorting capacitors, and the separation effect is obvious. The main process is through multi-tool crusher crushing, crushing, gravity sorting, eddy current sorting process. Capacitor recovery equipment adopts dry crushing, crushing to make electronic (capacitor) and other raw materials into metal and plastic, paper non-metallic mixture, and then through specific gravity separation and eddy current separation, so that aluminum and paper separation process route, in order to prevent dust pollution in the customization process, the equipment also uses a three-level dust collector, effectively solve the problem of dust pollution. Capacitor recovery equipment by special crusher, crusher, grading screen, sorting machine with a multi-unit structure to complete a multi-machine feeding, with automatic conveying equipment and sorting equipment to achieve the separation of metal and non-metal sorting recovery role.

Capacitor crushing recovery process:

1. Multi-cutter crusher: the waste capacitor is broken and decomposed.

2. Air sorting machine: carry out air sorting of the broken capacitor, separate the oil paper, separate the aluminum, rubber and electronic feet.

3. Magnetic separator: magnetic separation of the material after air separation, and magnetic selection of the electronic foot.

4. Eddy current separator: Separate aluminum and rubber.

Electronic component capacitive crushing equipment advantages:

1, the use of advanced multi-knife crushing, air separation, magnetic separation, eddy current separation of new technology, the separation of metal and non-metal after crushing separation, high degree, the separation effect can reach more than 99%;

2, the key technology is a variety of waste electronic components, capacitive components of the special crushing, crushing, magnetic separation equipment organic combination in the supply process to achieve a greater energy saving effect, and achieve a high metal separation rate.

Waste capacitor recovery equipment can separate the components on the waste circuit board, can separate all kinds of conductors and non-conductors, metal and non-metal separation, equipment is mainly used in waste electronic waste capacitor and aluminum plastic mixture of gold separation, separation effect is very obvious. Since the city has to eliminate a large amount of waste every year, waste capacitor recycling equipment can recycle these wastes, equipment energy saving and environmental protection, not only conducive to the recycling of resources, but also conducive to the stable long-term development of environmental protection.

Electronic components capacitance crushing equipment parameters:

| Type number | Work rate (kw) | Purity (%) | Utilization rate (%) | Output(kg) |

| 500 | 45 | 96%-99% | ≥99% | 400-500kg |

| 800 | 75 | 96%-99% | ≥99% | 700-800kg |

| 1000 | 95 | 96%-99% | ≥99% | 900-1000kg |

Waste capacitors are generally reported as waste from electronic components enterprises, or electronic components on circuit boards. Capacitors can be divided into: aluminum shell, aluminum foil, tin foot (also known as electronic foot, outer tin plated, inner copper plated, inside the iron needle, with magnetic), plastic paint shell, oil and paper. The smaller the capacitor, the higher the value, generally speaking, the capacitance aluminum content accounts for about 11%-26%, the tin foot accounts for about 15%, and the aluminum foil accounts for about 8%. Crushing and separating capacitors, the separation effect is obvious, the main process is through the multi-knife crusher crushing, crushing, magnetic separation, eddy current separation and other processes. Maoxin electronic components, capacitive crushing and recycling equipment, capacitive dissociation sorting equipment through many years of experiment and theoretical analysis, get good sorting effect. The impurities after separation are less than 1%, that is, the separation efficiency can reach more than 99%.

Why do you choose Copel recycling Equipment Capacitor processing and recovery equipment regional security service provider--Maoxin Machinery to call for cooperation? Focus on "cultural concept" recycling capacitors Capacitor processing and recovery equipment service provider -- Maoxin Machinery always believes that: corporate culture condenses the hearts of the people, and excellent talents shape high-quality products! Maoxin Machinery, which has adhered to the recycling capacitors field and created Capacitor processing and recovery equipment products with ingenuity for many years, has always attached great importance to the impact of cultural concepts on enterprises! Corporate culture is the soul and development cornerstone of Maoxin Machinery, and the formation of Maoxin Machinery corporate culture is by no means a result of one day.

Thank you for browsing the Copel recycling Equipment Capacitor processing and recovery equipment regional security service provider--Maoxin Machinery website [Capacitor processing and recovery equipment] products! Maoxin Machinery is a Capacitor processing and recovery equipment product Chinese supplier. Since its establishment, it has been deeply engaged in the recycling capacitors field and has to provide continuous innovation Capacitor processing and recovery equipment products for recycling capacitors customers! Maoxin are always looking for new opportunities and new ways of doing things.

Hi,Copel friends,Enter your name, email, and questions below and we will reply during business hours (8am - 5pm Beijing Time, Monday through Friday).

Gongyi City west Industrial Zone, Henan Province

Phone: +86 18539447368

Email: 18539447368@163.com

Whatsapp: +86 18539447368

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368