Lithium-ion batteries (hereinafter referred to as lithium batteries) have significant advantages such as high voltage, large specific capacity, long life and no memory effect, and have quickly occupied the power source market of portable electronic and electrical equipment since its commercialization, and the output has increased year by year. Lithium batteries are electronic consumables with a service life of about 3 years.

Dear customer Negative sheet crushing and recycling equipment, we are glad that you have found us in a wide range of information! Here is the relevant information organized by Negative sheet crushing and recycling equipment for you.

Waste lithium battery negative description:

Lithium-ion batteries (hereinafter referred to as lithium batteries) have significant advantages such as high voltage, large specific capacity, long life and no memory effect, and have quickly occupied the power source market of portable electronic and electrical equipment since its commercialization, and the output has increased year by year. Lithium batteries are electronic consumables with a service life of about 3 years. If the scrapped lithium battery is handled improperly, the lithium hexafluorophosphate, carbonate organic compounds and heavy metals such as cobalt and copper contained in it will inevitably pose a potential pollution threat to the environment. In order to alleviate the increasingly serious problem of resource shortage and environmental pollution caused by rapid economic development, it has become a global consensus to realize full component recycling of waste materials. The copper in the negative electrode of waste lithium batteries (the content of about 35%) is a widely used important supply raw material, and the toner adhered to it can be used as an additive such as plastic and rubber. Therefore, the effective separation of the negative electrode components of the waste lithium battery has a promoting effect on the realization of the waste lithium battery resource and the elimination of its corresponding environmental impact to a high extent. Commonly used waste lithium battery treatment methods include wet, fire and mechanical physical methods. Compared with the wet and fire methods, the mechanical physical method does not use chemical reagents, and has lower energy consumption, which is an environmentally friendly method. Based on the structural characteristics of the negative electrode of the lithium battery, the company adopts the combined process of crushing and screening and air separation to separate and screen the negative aluminum and carbon powder of the waste lithium battery.

Working principle of waste lithium battery positive and negative electrode recycling equipment:

Based on the negative structure of lithium battery and the material characteristics of copper and negative material, the negative material of waste lithium battery was separated and recovered by the combined process of hammer crushing, vibrating screen and air separation. ICP-AES was used to analyze the metal grade of experimental samples and separated and enriched products. The results show that after the crushing and screening of the negative electrode material, the grade of copper in the crushing material with particle size greater than 0.250 mm is 92.4%, and the grade of the negative electrode material in the crushing material with particle size less than 0.125 mm is 96.6%, which can be directly recovered. In the crushing material with particle size of 0.125~0.250 mm, the grade of copper is low, and the effective separation and recovery of copper and negative electrode material can be realized by air separation. In the process of air separation, the recovery rate of copper is 92.3% and the grade is 84.4% when the operating air velocity is 1.00m /s.

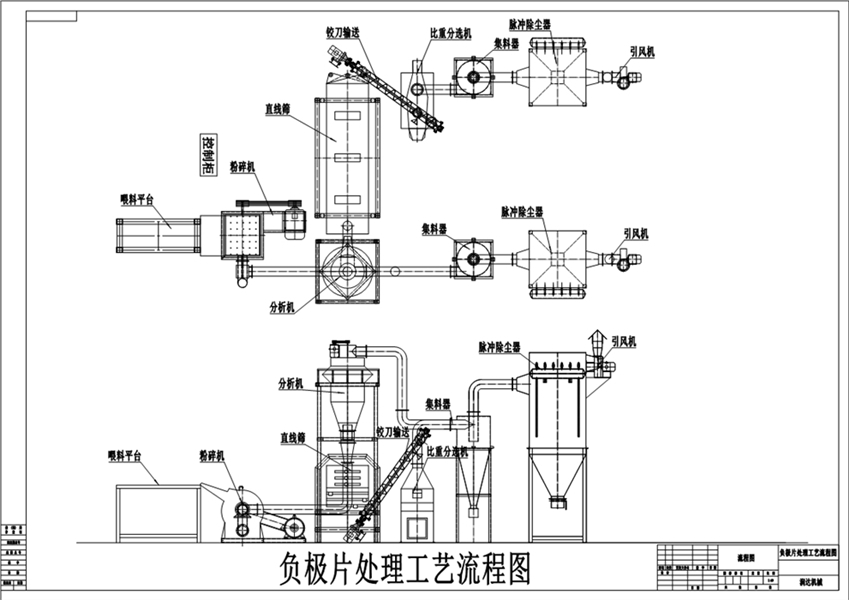

Negative plate processing process diagram:

1. Crusher: the material after air sorting is crushed.

2. Analytical machine: the material after grinding is separated by wind separation.

3. Linear screen: the materials sorted by the analysis machine are screened, and the metal materials and negative powder are sorted out respectively.

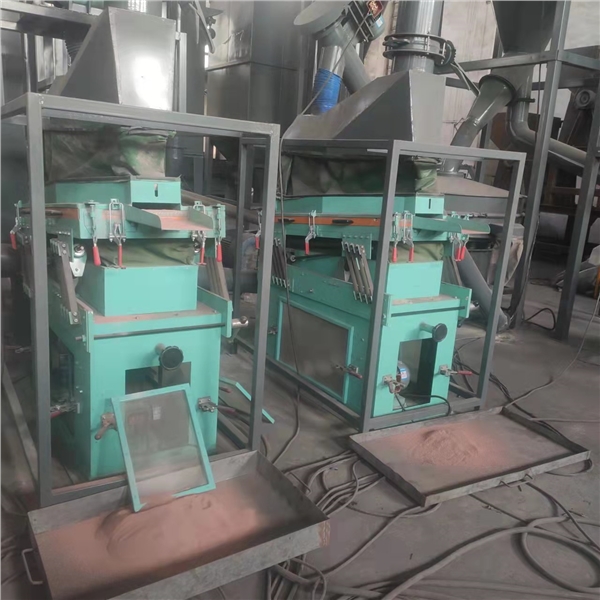

4. Specific gravity sorting machine: the metal and black powder mixture in the linear screen into the specific gravity sorting machine for sorting.

5. Collector: the positive powder is collected and discharged.

6. Pulse purifier: The dust generated in the operation of the whole equipment is collected and discharged.

Features of waste lithium battery negative electrode recovery equipment:

1. Through the combined process of hammer crushing, vibrating screening and air separation, the resource utilization of metal copper and negative electrode materials in waste lithium battery negative materials can be realized.

2. The negative material can be effectively separated from the carbon powder and copper foil by hammer vibration crushing, and then the copper foil and the negative material can be initially separated by vibration screening based on the size difference and shape difference between the particles. The results of hammer vibration stripping and screening showed that copper and anode materials were enriched in the particle size range of particle size greater than 0.250 mm and particle size less than 0.125 mm, respectively, with grades up to 92.4% and 96.6%, which could be directly sent to downstream enterprises for recycling.

3, for the particle size of 0.125~0.250 mm and low copper grade broken particles, the use of air separation to achieve effective separation between copper and negative material, when the air speed is 1.00 m/s can achieve good recovery effect, copper recovery rate can reach 99.5%, grade reached 84.4%.

4, the equipment is mainly used for lithium-ion battery supply companies, the negative electrode material in the scrap negative electrode sheet for separation and treatment for recycling purposes. The complete set of equipment operates in the negative pressure state, no dust leakage, and the separation efficiency can reach more than 98%.

Scope of supply and configuration of main components:

|

Serial number |

Part name |

Main component material |

Model number |

Power(kw) |

Unit |

Quantity |

Remark |

|

1 |

Feeding platform |

Q235 |

1500 |

|

Piece |

1 |

|

|

2 |

Pulverizer |

Q235 |

1000 |

55 |

Set |

1 |

|

|

3 |

Analytical engine |

Q235 |

1200 |

2.2 |

Set |

1 |

|

|

4 |

Rectilinear screen |

Q235 |

3000 |

2*0.75 |

Set |

1 |

|

|

5 |

Specific gravity sorting machine |

Q235 |

1200 |

1.5+0.37 |

Set |

1 |

|

|

6 |

Reamer transfer |

Q235 |

219 |

1.5 |

Set |

1 |

|

|

7 |

Accumulator |

Q235 |

800 |

0.75 |

piece |

2 |

|

|

8 |

Pulse dust collector |

Q235 |

MC-64 |

|

Set |

1 |

|

|

9 |

Pulse dust collector |

Q235 |

MC-48 |

|

Set |

1 |

|

|

10 |

Induced draft fan |

Q235 |

F75 |

11 |

Set |

1 |

|

|

11 |

Induced draft fan |

Q235 |

F11 |

7.5 |

Set |

1 |

|

|

12 |

Connecting pipes and other |

Q235 |

|

|

Set |

1 |

|

|

13 |

Control cabinet |

|

3000*400*500 |

|

Set |

1 |

Many Negative sheet crushing and recycling equipment customers choose Africa crushing equipment Negative sheet crushing and recycling equipment rest assured enterprises--Maoxin Machinery Cabinda overseas product promotion station. The key word "win-win culture" recycling waste lithium batteries Negative sheet crushing and recycling equipment service provider - Maoxin Machinery people know that corporate culture is one of the core competitiveness of the enterprise. Many recycling waste lithium batteries Negative sheet crushing and recycling equipment enterprises put corporate culture on the agenda. From the corporate culture of a recycling waste lithium batteries company, we can see the future development prospects of the enterprise. Maoxin Machinery, as a company focused on serving recycling waste lithium batteries customers, has been committed to the creation of Maoxin Machinery culture. Since its establishment, Maoxin Machinery has always taken "gathering excellent talents and casting reassuring products" as its development goal, adhered to the Maoxin Machinery concept of "creating great business with one heart and one mind and seeking development", and adhered to the belief of "creating profits for shareholders, seeking benefits for Maoxin Machinery employees, and contributing value to society", and continued to move forward step by step!

China export products!Speak less and do more! No amount of rhetoric and packaging planning can match putting in effort on products!Maoxin precipitates the brand value of Negative sheet crushing and recycling equipment through daily actions!

|

|

In the online marketplace, differentiation is the key to winning business. Your product needs to stand out. Please contact us.

Gongyi City west Industrial Zone, Henan Province

Phone: +86 18539447368

Email: 18539447368@163.com

Whatsapp: +86 18539447368

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368