Scrap circuit board crushing and recycling supply line is mainly used for the separation of metal and non-metal in scrap circuit board, copper-clad board, circuit board and scrap material. The successful development of the machine not only improves the quality of recovered copper, but also prevents secondary pollution.

Dear [Board recovery equipment] customer, it is very lucky that you can find us in the vast information! Serving More International Customers with Durable Chinese Products! Henan Maoxin Machinery Equipment Co., Ltd is a Board recovery equipment product supply enterprise. Since its establishment, it has devoted itself to the Lithium battery circuit board crushing and recycling equipment field and to provide technical improvement Board recovery equipment products for Lithium battery circuit board crushing and recycling equipment customers! On the road to success, we walk together! The following is the relevant information of Board recovery equipment product organized by Maoxin for you.

Electrical (wire) board recovery equipment introduction:

Scrap circuit board crushing and recycling supply line is mainly used for the separation of metal and non-metal in scrap circuit board, copper-clad board, circuit board and scrap material. The successful development of the machine not only improves the quality of recovered copper, but also prevents secondary pollution. In this supply line, the waste circuit board is regenerated and customized by secondary crushing to make it into a mixture of metal and resin fiber powder. The metal is then separated from the resin by wind and electrostatic separation. In order to prevent the dust pollution in the customization process, the pulse dust removal device is added after the air separation process to effectively solve the problem of dust pollution.

Electrical (wire) board recycling equipment product introduction;

Scrap board crushing and recycling supply line is mainly used for the separation of metal and non-metal in scrap circuit board, copper-clad board, circuit board and scrap material.

1, the comprehensive performance is good, the computer board recycling, computer board recycling, TV board recycling and other line control board recycling has an effect. The recycling of various circuit boards containing capacitors is also compatible.

2, this supply line is the upgrade of type A products, on the basis of type A reduced power consumption, no noise, less labor automation program, high efficiency, while occupying a small area, is the ideal supply line of waste circuit board recycling to the present.

3, the whole set of equipment uses a new dust collector, three-in-one dust removal (cyclone dust removal + electrostatic dust removal + static dust removal) on the air, no exhaust emissions.

4, the appearance of the equipment is clean, no dust bag, replacing the traditional dust collector dust, odor can not solve the problem.

5, in order to prevent dust pollution in the customization process, pulse dust removal device is added after the air sorting process to effectively solve the problem of dust pollution.

Electrical (wire) board recovery equipment features:

1. The circuit board crusher is used for mechanical crushing and high voltage electrostatic separation. After disassembly, crushing and dissociation, the separation of metal and non-metal is carried out with high purity. The separation purity of the circuit board recycling equipment reaches more than 99.5%.

2. The key technology is to organically combine the special crushing and dissociating equipment of various waste circuit boards, achieve greater energy saving effect in the supply process, and achieve a high metal separation rate.

3. The unit energy consumption per ton of waste circuit board processed by circuit board recycling equipment is only about 3/5 of similar domestic products; A single unit can handle up to 1 ton per hour.

4. The price of circuit board recycling equipment is only 1/5-1/3 of similar equipment at home and abroad, and the recovery rate of copper is 3%-5% higher than that of similar supply companies.

5. Good comprehensive performance, it has effect on computer board, computer board, TV board and other line control board. The recycling of various circuit boards containing capacitors is also compatible.

6. Circuit board recycling equipment supply line is the upgrade of wind selection products, less power consumption than wind selection, and no noise, less labor and high automation procedures, improve efficiency, while occupying a small area, is the waste circuit board recycling, the current ideal supply line.

7. Less labor, no noise, and flexible placement of circuit board recycling equipment.

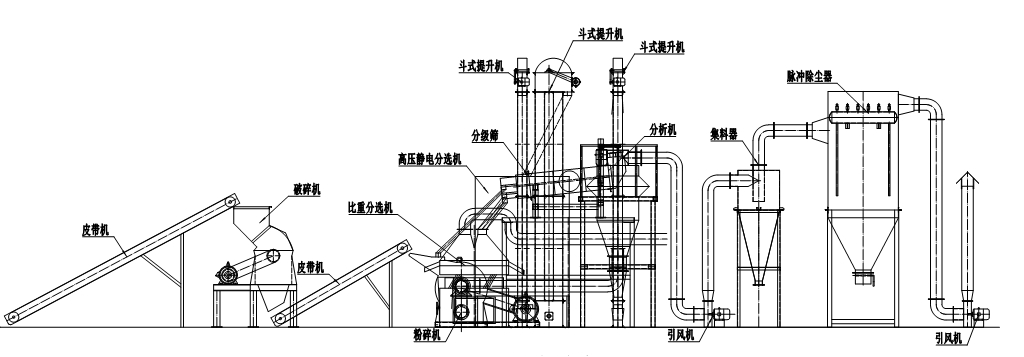

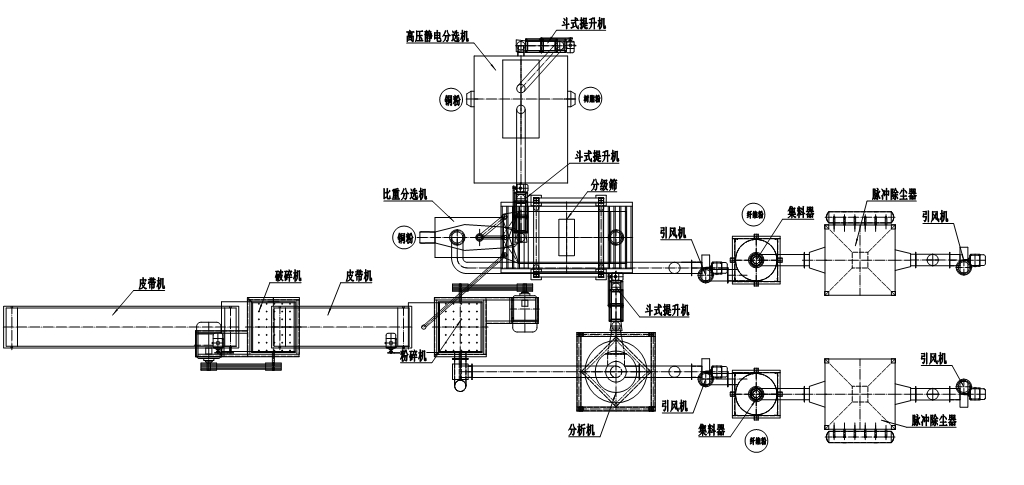

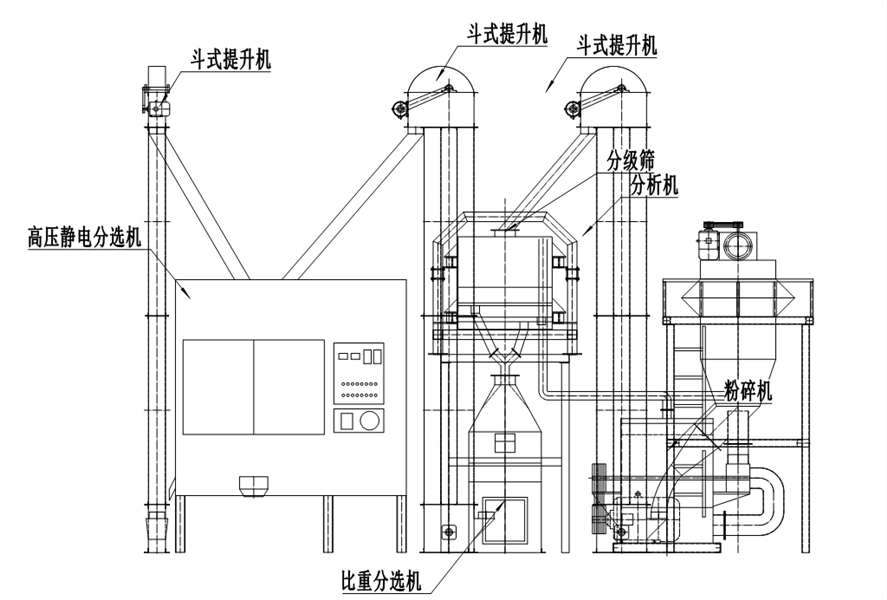

Circuit board layout process plan:

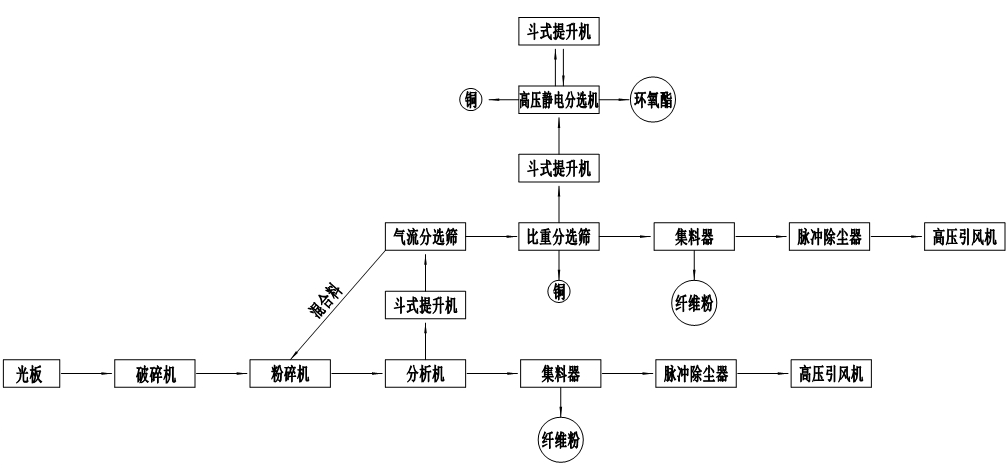

Circuit board crushing recovery process:

Process diagram

1. Shredder: shred the light plate to 2-3 cm.

2. Circuit board crusher: the broken circuit board is crushed, crushed to about 20 mesh.

3. Analytical machine: the pulverized material is air selected, the resin, copper and dust, fiber are separated, dust and fiber are sucked into the collector by the induced draft fan, and the resin and copper enter the classification screen.

4. Collector: the dust and fiber are collected, and the collected fiber is discharged.

5. Pulse purifier: Collect the dust and microfibers generated in the crushing process.

6. Grading screen: the resin and copper are screened, the resin and copper that have not been separated are returned to the host and then crushed, and the separated resin and copper enter the specific gravity sorting machine for sorting.

7. Specific gravity sorting: the tree fat powder and copper for specific gravity sorting, because the weight of copper is greater than the weight of the resin, the copper will be sorted to one side, the resin is sorted to the other side. In this way, the metal is separated from the non-metal. This is an advanced technology in China, which can achieve more than 99% metal sorting effect.

8. High voltage electrostatic separation: the tail of the specific gravity sorting machine is then high-voltage electrostatic separation, so that the small copper powder contained in the tail is separated from the resin (the principle of high voltage electrostatic separation is: the input power supply is adjusted by the transformer to a high voltage of 100,000 volts, forming a high voltage magnetic field, which has the effect of adsorption on conductive metals, so as to achieve the separation of metal and non-metal)

Economic benefit analysis of electrical (wire) board recycling equipment:

The total power of the supply line is 98Kw, the processing capacity is 700Kg/h, the copper content of the circuit board is about 18%(the copper content of the waste circuit board is different, generally 13%-35%), and the operator is 5 people.

(1) Estimated output value (300 days per year, 8 hours per day)

(a) Annual copper output: 300(days)×8(hours)×700(Kg)×18%(copper content)=302.4 (tons) Copper according to 50,000 yuan/ton, the annual copper value is: 302.4×5 =1512(million yuan)

(b) Annual output of glass fiber powder: 300(days)×8(hours)×700(Kg)×82%(content)=1377.6 (tons) Glass fiber according to 1000 yuan/ton, the annual output of non-metallic material value: 1377.6×0.1(million yuan)=137.76 (million yuan)

(c) Total annual output value :1512+137.76=1649.76 (ten thousand yuan)

(2) Cost estimation

(a) Annual electricity consumption (calculated by 0.8 yuan/KWH) : 100(Kw)×300(days)×8(hours)×0.8(Yuan/KWH)=19.2 (ten thousand yuan)

(b) Labor cost 2000(RMB/person/month)×12(month)×5(person)= 120,000 (10,000 yuan)

(c) Depreciation of equipment (10% depreciation), about: 260,000 ×10%=2.6 (ten thousand yuan)

(d) Maintenance fee: about 10,000 yuan

(e) Waste circuit board acquisition fee: 300(days)×8(hours)×700(Kg/h)×6(Yuan /Kg)= 1,008 (million yuan)

(f) Rental fee: 2000(Yuan/month)×12(month)= 24,000

(f) Total: 19.2+12+2.6+1+1008+2.4= 10,344.2 (ten thousand Yuan)

Gross profit: 1649.76-1034.2=615.56 (ten thousand yuan)

Electrical (wire) board recovery equipment technical parameters:

|

Serial number |

Device name |

Model number |

Power(kw) |

Number of pieces (set) |

|

|

1 |

Belt conveyor |

500 |

1.5 |

2 |

|

|

2 |

Shredder |

800 |

22*2 |

1 |

|

|

3 |

Pulverizer |

1000 |

55 |

1 |

|

|

4 |

Analytical engine |

1000 |

2.2 |

1 |

|

|

5 |

Accumulator |

800 |

|

2 |

|

|

6 |

Pulse dust collector |

MC-64 |

|

1 |

|

|

7 |

Pulse dust collector |

MC-48 |

|

1 |

|

|

8 |

Induced draft fan |

F11 |

11 |

1 |

|

|

9 |

Induced draft fan |

F75 |

7.5 |

1 |

|

|

10 |

Rotary vibrating screen |

1600 |

1.1 |

1 |

|

|

11 |

Hoister |

800 |

1.1 |

3 |

|

|

12 |

Specific gravity sorting machine |

1200 |

1.5+0.75 |

1 |

|

|

13 |

High voltage electrostatic sorting machine |

1200 |

1.1+2.2 |

1 |

|

|

14 |

Air shutter |

160 |

0.75 |

2 |

|

|

15 |

Connecting pipe |

219、273 |

|

A set |

Elbow, Straight pipe |

|

16 |

Air regulating valve |

200 |

|

2 |

|

|

17 |

Pc tube |

110 |

|

A set |

Joints, Elbows |

|

18 |

Connecting hose |

180、120 |

|

4 roots |

|

|

19 |

All equipment brackets |

|

|

Complete set |

|

|

20 |

Distribution cabinet |

|

|

1 |

Henan Maoxin Machinery Equipment Co., Ltd. supplies waste electronic waste recycling and crushing separation equipment, forming electronic waste environmental protection treatment equipment supply, waste electrical and electronic products recycling and dismantling disposal. In combination with the current environmental protection needs at the same time launched a series of environmentally friendly mechanical products: environmentally friendly waste lithium battery crushing and recycling, mobile phone lithium battery crushing and separation equipment, environmentally friendly waste circuit board, circuit board one-stop recycling - crushing - separation - reuse supply line, environmentally friendly waste cable and wire recycling and separation equipment, environmentally friendly waste aluminum plastic recycling equipment. We provide professional technology for investment customers, providing visits, trial machines, on-site discussions, etc., because of professional focus, integrity, reliability, and perfect service.

In today's intelligent manufacturing industry, the craftsman spirit is not outdated. China export products !For many years, Henan Maoxin Machinery Equipment Co., Ltd has focused on the Lithium battery circuit board crushing and recycling equipment field and polished the "craftsman" level talents on Board recovery equipment and other products! Welcome to call. Wish you We are dedicated to providing you with the highest quality products and services.!

Hi, friends,If you want to know more information about Board recovery equipment product, pls kindly leave your phone number, We will back to you ASAP once we got your message.

Gongyi City west Industrial Zone, Henan Province

Phone: +86 18539447368

Whatsapp: {whatsapp}

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368