As a kind of treatment equipment for environmental protection waste gas treatment, it is divided into circulating water spray tower according to its working principle. According to the material of the tower, it is divided into fiberglass spray tower, pp spray tower and stainless steel spray tower.

Dear [Water spray tower equipment] customer, it is very lucky that you can find us in the vast information!Create brilliance with cohesion!Since its establishment, Maoxin has been deeply involved in the Lithium battery circuit board crushing and recycling equipment field and has provide stable performance Water spray tower equipment products for Lithium battery circuit board crushing and recycling equipment customers! The following is the relevant information of Water spray tower equipment product organized by Henan Maoxin Machinery Equipment Co., Ltd for you. Maoxin are willing to provide you with new Water spray tower equipment information to help you make a correct choice!

Spray tower equipment introduction:

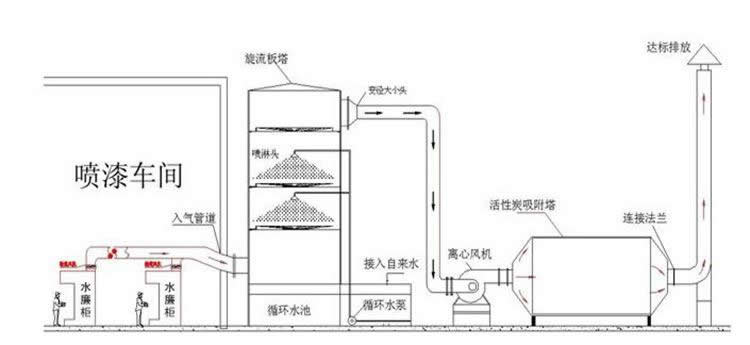

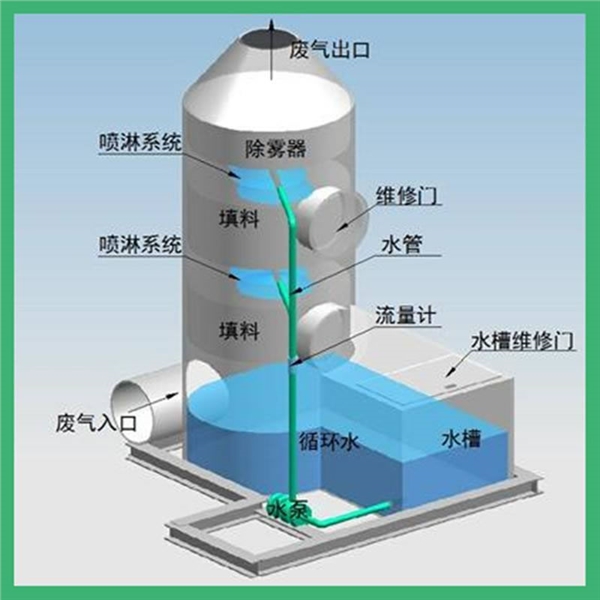

As a kind of treatment equipment for environmental protection waste gas treatment, it is divided into circulating water spray tower according to its working principle. According to the material of the tower, it is divided into fiberglass spray tower, pp spray tower and stainless steel spray tower. According to the different nature of the exhaust gas, choose a reasonable spray material and spray process. The exhaust gas is introduced into the PP spray tower by the air pipe, and through the packing layer, the exhaust gas and sodium hydroxide absorption liquid are fully in contact with the gas-liquid two-phase absorption and neutralization reaction. After purification, the acid mist exhaust gas is discharged into the atmosphere by the fan after dewatering and defogging by the defogging plate. The absorbing liquid is supercharged by the pump at the bottom of the tower, sprayed down the top of the tower, and then returned to the bottom of the tower for recycling. The purified acid fog exhaust gas meets the emission requirements of the local emission standards and is lower than the national emission standards.

When the dusty waste gas or oily waste gas passes through the spray tower body, the liquid medium, some of which is lye and some of which is sulfuric acid solution, is ejected from the appropriate position inside the tower body (according to the design). If the exhaust gas contains acid, choose lye spray to neutralize the acid, if the exhaust gas contains alkaline, choose sulfuric acid solution absorption. The specific choice of acid and base solution depends on the nature of the waste gas and the enterprise's own situation. The waste gas without acid and alkali but containing oil and dust can be treated by circulating aqueous solution spray. When the exhaust gas enters from the bottom of the tower, it will contact with the spray medium emitted by the spray tower. After contact, the exhaust gas or oil pollution will be wrapped by water beads, and the water beads wrapped in pollutants will collide again, and the surface area and gravity will increase. In the case of increasing gravity, water droplets containing pollutants fall to the bottom of the spray tower under the influence of gravity, heavier pollutants sink to the bottom of the tower body, and lighter pollutants float on the surface of the circulating water body.

Spray tower design considerations

1, when the exhaust gas contains oil and dust, it is necessary to consider whether to add filter filler or nozzle type in the design of the spray tower. The choice of improper nozzle is easy to cause the blockage of the water system of the spray tower.

2, choose the right spray medium.

3, the design of reasonable airflow channels, and water supply mode.

4, spray tower after the sewage discharge and cleaning problems.

5, the right gas-liquid ratio, through the gas-liquid ratio to choose the right pump.

6, empty tower flow rate is generally designed 1-6 m/s. However, in the case of medium spray and filler, the filtration speed can be reasonably selected according to the specific conditions of the exhaust gas.

International operation, service in Asia, Africa and Latin America customers! How to make Maoxin [Water spray tower equipment] quality stable and reliable, create greater customer value, and provide advanced products for the international market is the direction that Maoxin are committed to pursuing!Hope our negotiation is as exciting as the possibility of our future cooperation.

We are happy to help you

Contact Maoxin today for all your questions regarding Water spray tower equipment or specific applications that may require a custom solution. We normally respond the same day.

Gongyi City west Industrial Zone, Henan Province

Phone: +86 18539447368

Whatsapp: {whatsapp}

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368