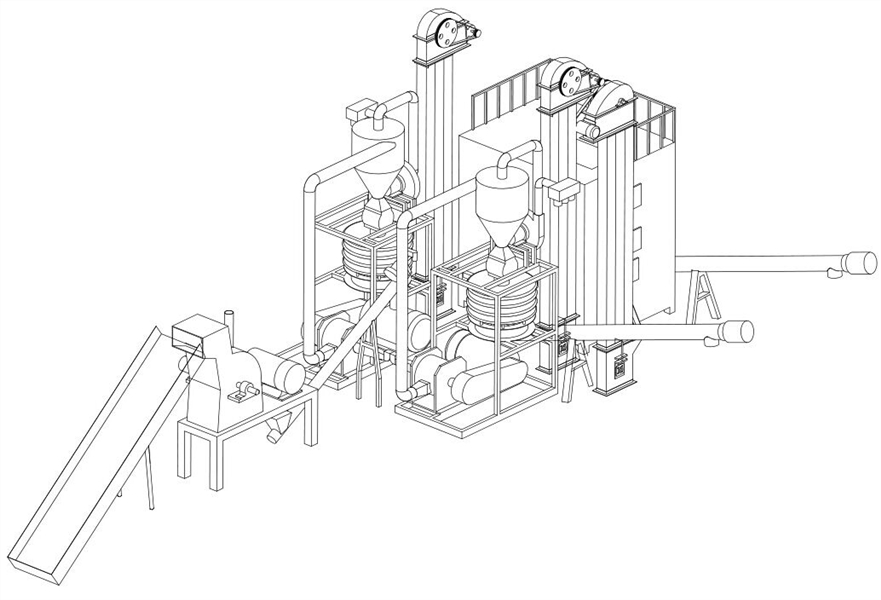

Aluminum plastic crusher with tool steel, special tool, very durable, tool installation design can be adjusted telescopic, with blunt grinding can be repeatedly used, long service life. The mechanical tool holder for aluminum plastic crushing is a step shear design, which decomposes the cutting force and causes the cutting force to increase exponentially.

Aluminum-plastic separation crusher

Aluminum plastic crusher with tool steel, special tool, very durable, tool installation design can be adjusted telescopic, with blunt grinding can be repeatedly used, long service life. The mechanical tool holder for aluminum plastic crushing is a step shear design, which decomposes the cutting force and causes the cutting force to increase exponentially. Tool holder material is excellent tool steel, rigid and flexible reasonable, not easy to break or wear, using high strength steel screws (8.8 class) fastening, solid and durable structure. The main body of the aluminum plastic crusher is thick wall excellent structural steel material, which can avoid affecting the mechanical properties due to long-term crushing materials. The main axis and double end face of the alumino-plastic crusher are customized by the high-precision coordinate machine at one time to ensure that the error of concentricity and verticality is not more than 0.05MM, and each component is set to the benchmark hole and surface for coarse and fine water customization, with strong component interchangeability and high precision.

Main features of aluminum plastic crusher:

The spindle rotation diameter is large, the capacity of the crushing chamber is large, the unique cutter shaft design has a strong grip on the hollow products, and the shell is made of solid welded steel structure, which has a wide range of versatility. According to the different crushing material, our company can provide different rotor design can also break the gate, pipe, profile, sheet, film and large nozzle material. The machine has many advantages such as economy, durability, easy cleaning, long service life, etc. The blade material is made of wear-resistant, tough SKD-11 alloy blade. Large hollow thin-wall plastic products, large hollow packaging boxes, large plastic boxes, plastic frames, refrigerator shells, TV plastic shells) plastic products can be directly broken without decomposition or flattening.

Aluminum-plastic separation equipment application scope:

This series of new aluminum-plastic grinding machine is a series of grinding machine developed by our company absorbing technological innovation at home and abroad. Used for PVC plastics with low to medium hardness, high density PE, or other aluminum-plastic after trial grinding success. It has been proved by the practical operation of professional industrial and mining enterprises of plastic products that the pulverized powder is added 20%-30% calcium carbonate in the customized return visit, and the chemical and physical properties of its products remain the same as the new indicators and the output can reach 300kg. Therefore, the aluminum-plastic mill is a equipment for plastic products enterprises to reduce costs and solve the accumulation of waste products.

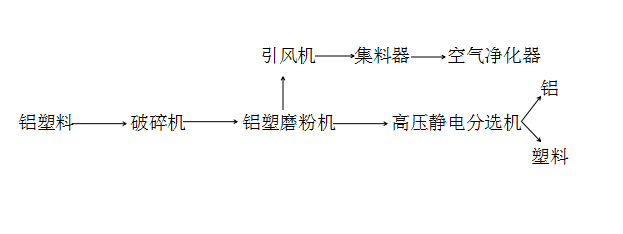

Working principle of aluminum-plastic separation equipment:

The working part of the machine is divided into cutter head. The high-speed particles are partially crushed after hitting the tooth plate and extracted by suction air, while the larger particles continue to impact and are extracted after crushing. In this way, the cutter load is reduced, the grinding efficiency is improved, and the powder is cooled evenly.

Advantages of aluminum and plastic separation equipment:

Low temperature is the main advantage of the machine. According to thermal energy equivalent: convert to 860 kcal of heat after work per hour. This machine is for external ventilation. Air volume up to 50m/KW From the inlet and outlet wind temperature difference, take away most of the heat. A small part of the heat is settled by water cooling. It is required that the inlet temperature of cold water is not greater than 25 ° C, the outlet water temperature is not greater than 45 ° C, and the cooling water flow is appropriately increased in summer to reduce the temperature.

Aluminum-plastic separation equipment machine parameters:

|

Number of cutters: 1, outer diameter: 483mm± 1mm |

Tooth plate: 1 pay 12 pieces (excellent alloy, hardness 50°-58°) |

|

Blade: 24 pieces (fine and diamond, hardness 52-55) |

Main motor speed: 2950r/min |

|

Main motor power: 37KW, with triangle belt: B type, 2007mm |

Induced draft fan: Model 9-19, 4#, equipped with 3KW motor |

|

Fan off: Model ZGF, equipped with motor 0.75KW |

Output: PVC20-100 mesh 180-280kg/h |

|

Size: Complete set of machine (length * width * height) 5900*1450*2900 |

Weight: 1200kg |

18539447368@163.com

18539447368@163.com  +86 18539447368

+86 18539447368